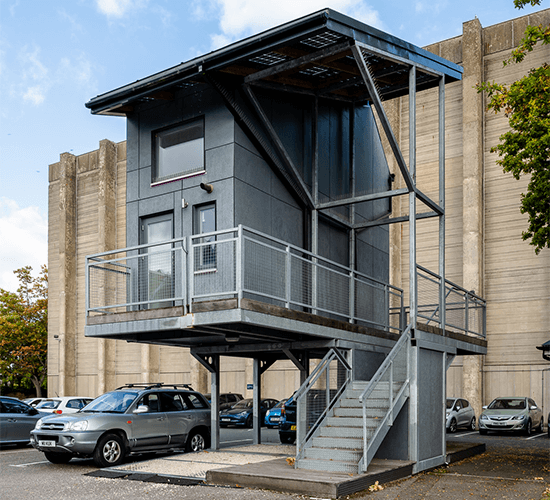

The Seismic commercial building

Smart modular construction is an attractive option for the construction industry. Buildings can be constructed faster and more affordably, thanks to volumetric constructions, sub-assemblies, components, pods, panellised systems, and site-based modern methods of construction (MMC).

Launched in 2022, the Seismic commercial building at the BRE Science Park shows how platform-based construction can exceed Construction 2025 targets in delivery, carbon, and cost. The Seismic commercial building was partially constructed off site, using a standardised steel frame and set of standard components, so modules from three different manufacturers could be combined in one building. McAvoy Group systems were used on the ground floor, Algeco (formerly the Elliott Group) on the top floor, and Tata Steel provided the ceiling and roof. A standardised approach maximises compatibility and reduces waste Companies can work together more efficiently, and the process from design to assembly is faster.

|

Features of the Seismic commercial building

Once built, Seismic used SPECIFIC’s expertise to assess the building’s carbon impact, looking at its whole life from design and materials through to manufacturing and performance. The whole-life analysis found that Seismic has a significantly lower carbon impact than traditional construction.

Active Building elements are included: rooftop solar (BIPV), battery storage, car charging, and energy monitoring.

The building was designed with the UK Government’s Construction 2025 targets in mind, and exceeds them all. Compared to traditional construction, the building is:

75% more efficient in delivery

70% lower in carbon impact (both embodied and operational)

47% better in value

The team behind the building

Seismic is a consortium of 7 different companies led by blacc, and includes the Manufacturing Technology Centre, the National Composites Centre, and SPECIFIC.

More about modular construction

The benefits of modular construction include:

Speed of construction – indoor production lines are not affected by adverse weather, so buildings can go up faster.

Consistent high quality – standards can be controlled more easily in a factory-built environment, including acoustic, durability, fire, security, resilience, structural, sustainability and wellbeing.

Flexibility – modular constructions can be assembled and disassembled for relocation, refurbishment and re-use.

Lower cost – lower upfront costs mean a faster return on investment.

Reduced waste – factory production and consistent designs minimise component waste by up to 70-90% waste savings, according to the Waste & Resources Action Programme (WRAP).

More environmentally friendly – spending less time on building sites means less impact on surrounding businesses, households and road networks.

Explore the Innovation Zone at the BRE Science Park

Flood Resilient Repair House at the BRE Science Park

Üserhuus Configurable Housing at the BRE Science Park

Testing Facilities at the BRE Science Park

Sign up to our newsletters

Get the latest updates and offers on our products, events, standards and qualifications.

Sign up