Rail station in Bergen gets Very Good BREEAM Infrastructure rating

Overview

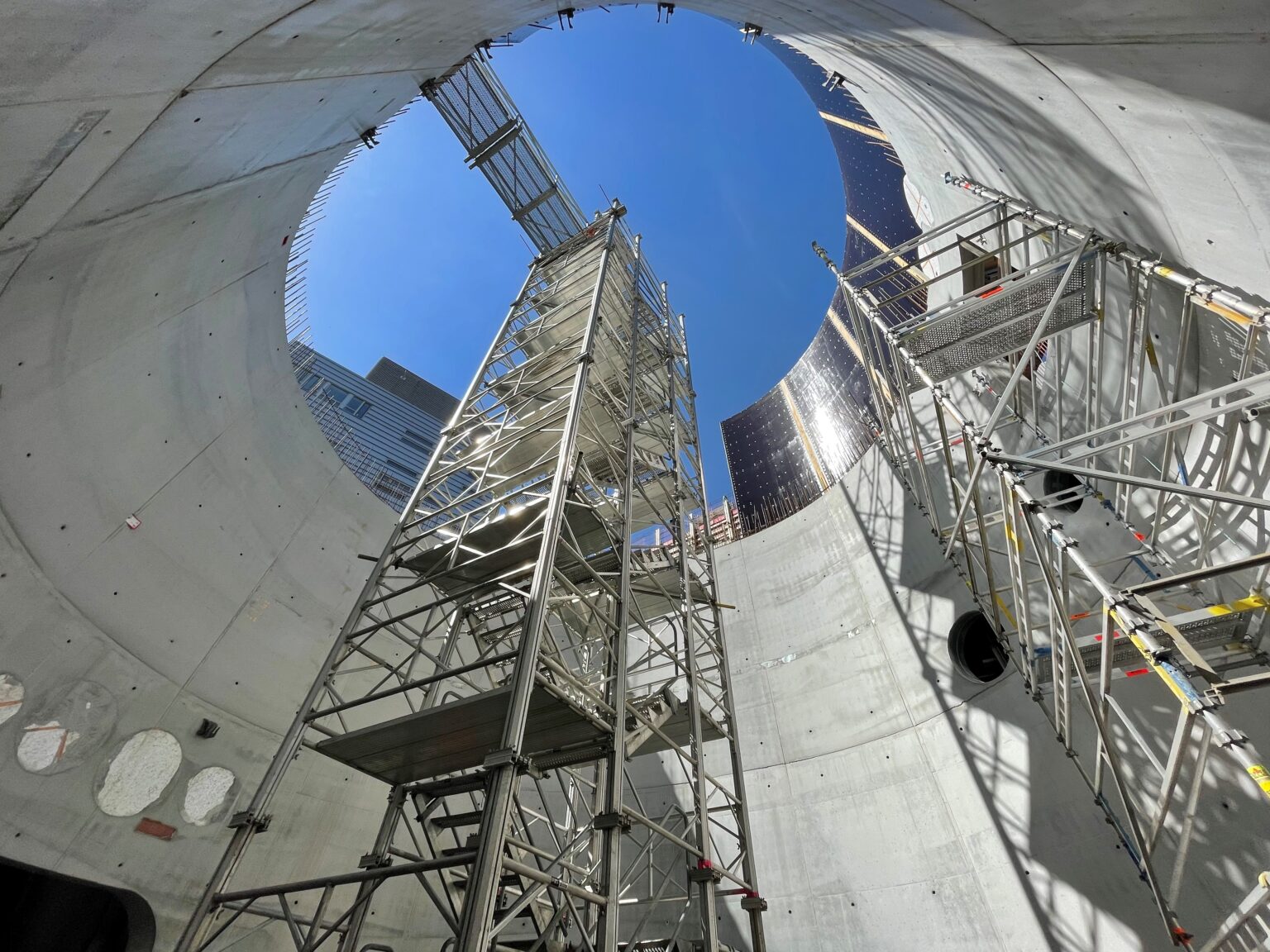

The station was constructed 30 metres below ground between two hospitals, Haukeland University and Haraldsplass Diakonale in Bergen, Norway. For its sustainable practices, including reducing waste and carbon emissions, the project team was awarded a BREEAM Infrastructure (formerly known as CEEQUAL) rating of ‘Very Good’.

About

Bybanen Utbygging is the Norwegian government body that managed the construction projects with Bybanen towards Åsane.

Background

Bybanen D13 Haukeland Holdeplass was the first underground station at the light rail system to improve public transport in Bergen, Norway. The D13 contract is one of several contracts in a larger development scheme called Bybanen building stage 4, which is a new 9km line to the suburb of Fyllingsdalen.

Challenges

A spokesperson shared, “The main challenges for the project were the size of the construction site. The site is small, confined, and located in a populated area in Bergen. Also, most of the construction works occurred underground, which created complex logistics. Planning activities ahead of time was crucial to avoid significant impact on the construction operations, environment, and safety. In addition, the project is near hospitals, which has been an important factor for managing traffic and minimise risk to all road users.”

The work included:

Building the station area.

Two shafts and entrance buildings, including architectural furnishing.

Underground walkways with lifts and escalators.

Improving the surrounding landscape and existing infrastructure.

The underground station connects the hospitals, businesses, and residents to the light rail network and will improve the mobility demands and urban growth in the area.

Solutions

Management

The project incorporated collaborative planning (lean) throughout the duration of the project. It gives everyone the opportunity to gather knowledge and understanding of the main activities and work schedule. Communication between the workforce and project team was an important component to achieve good management. Combined with monthly meetings with the workforce regarding construction progress, safety, environmental, and financial topics has given more awareness and engagement.

Stakeholders and communities

The contractor in cooperation with the client has had an ongoing community engagement and has established relations with the local community and stakeholders. The contractor has engaged and interacted with the public through several communication channels, such as social media, project website and a dedicated neighbour contact. The project achieved great communication and involved the residents in environmental, social and economic aspects. The dialog between the parties and feedback has been overall positive.

Resources and waste

The project team has during construction considered material use and efficiency within the context of reducing environmental impacts. For example, the majority of the concrete structures are built with low-carbon concrete with emissions <220 kg CO2 equivalents/m3 (low-carbon class A). The carbon emission from concrete production and concrete quality has been of great importance for the client and contractor, due to the extent of exposed concrete is in the public space, high amounts of concrete used in the building, and the client environmental goals within reducing carbon emissions.

In addition, the project has focused on waste management and finding productive solutions to minimising waste, waste handling on site and waste transfer. There have been several measures implemented to ensure best practice. Hence, the project has achieved a waste sorting of 95%.

Key metrics:

Embodied carbon emissions

1,350 tonnes CO2 equivalent - 33% reduction achieved

Waste diverted from landfill

2,640 tonnes - 68.8% of total waste

Transportation and logistics

The contractor has to a large degree used local firms and suppliers with a short driving distance to the site. Thus, the project has had a significant local profile. The transportation has mainly been through the underground tunnel system and has reduced the environmental impacts, especially with regards to traffic congestion on the local road network and to minimise the potential hazard to vulnerable road users.

Also, the project team wants to promote sustainable transportation options and has used electric vehicles and electric scooters for transportation of personel on site. The project team has encouraged the workforce to commute more environmentally friendly and established bike amenities at the construction grounds.

Benefits

A spokesperson for the project commented, “BREEAM Infrastructure has been a great tool to encourage sustainability development during construction. The contractor, designer and the client have all worked together, to find solutions within optimising building elements, resource efficiency and taking actions to minimise further impacts on the environment.”

They continued, “By applying BREEAM infrastructure during construction all project participants are involved in searching for new operation methods and finding new solutions for resource efficiency and minimising materials usage. As a result, it has had a financial effect and reduced material cost.”

The project has specific sustainability targets for the construction phase and has developed a project-level policy to further commit to a responsible construction. Good communication towards residents, reducing CO2 emissions, reuse material, good waste sorting and electric vehicles are some examples of main targets during construction stage.”

Examples of best practice and innovation during construction are:

Collecting and returning washing water from cleaning concrete trucks. The water is delivered back to supplier and reused in the concrete production.

Applying BIM model and scanning to make precut formwork to fit uneven rock surfaces.

Monthly reports including environmental issues and monitoring sustainability targets through weekly and monthly site inspection.

Digitising and mobilising drawings for workforce and improve productivity on site with new technology.

Reflecting on the overall success of this project, Mona Løvås, Project manager at Bybanen Utbygging, shared, “Breeam has contributed to creating a system of communication with neighbours in a challenging area. There are two hospitals in immediate proximity, heavy traffic and several demanding residents next to the construction site. The contractor has carried out the project in an exemplary manner and has received great feedback from neighbours in terms of sharing information and construction activities.”