Environmental Product Declaration - EN 15804

What is an Environmental Product Declaration (EPD)?

An EPD measures the environmental impact of a product. It is generated based on data obtained through life cycle assessment (LCA). An LCA is performed using a peer-reviewed Product Category Rules document (PCR) in line with the European standard EN 15804, ISO 14025, and other related international standards.

EPDs have many uses within an organisation. They can be used as marketing material and for the improvement of product manufacture or process efficiency. They can feed into whole building assessment schemes and other comparative tools. They can also inform building information modelling (BIM) computer-aided design (CAD) software to make comparisons and assess design options that improve a building’s environmental performance.

Benefits of an EPD

With an EPD, you can:

Provide quantified data on your products environmental impacts, such as embodied carbon, ozone, acidification and more.

Exceed customer demands and specifications with increased transparency.

Boost your product’s reputation through internationally recognised standards.

Enable whole life cycle management

Support innovative product development, such as improving efficiency for energy, materials and transport costs.

Get recognised by building assessment schemes, such as BREEAM , LEED, DGNB and Green Star.

Why choose BRE?

BRE is internationally recognised for its expertise in LCAs. We consulted industry stakeholders to develop a comprehensive EPD scheme in line with the European standard EN 15804.

The verification mark represents quality and illustrates that a product has gone through a rigorous verification process.

Membership of BRE’s Verified Environmental Product Declaration Scheme is cost effective and provides a fast-track route to meeting the obligations of EN 15804. Independent expertise delivers better quality outcomes, saving time in the longer term.

EPDs issued by BRE are automatically added to IMPACT, the BRE building-level LCA database and tool certification required for application of LCA within BREEAM.

EPD support a projects BREEAM rating with:

Mat 01 Building life cycle assessment. The data presented in the EPD results tables can be used within a building level life cycle assessment to demonstrate how different options have been considered to improve the design. Seven credits are available in this section including two credits for building performance against a benchmark.

Mat 02 Environmental Impacts from construction products. Up to 1.5 credits are available for using at least 20 products in the build that have their own product specific EPD.

EPDs are typically valid for five years. Some manufacturers may update an EPD before it expires to reflect its latest efficiency gains, composition or new technologies that improve the results. After five years, an EPD can be extended for a further five years, providing the manufacturer can give sufficient evidence that no significant changes have occurred to the manufacturing process.

The life cycle assessment is a desktop exercise requiring information to be gathered relating to the factory’s material consumption, energy, water and waste typically for one full production year. The data collection form typically used can be found here.

The types of EPD include:

Average product or manufacturer-specific product

Product range or product-specific

Declared unit or functional unit

Business to business or business to consumer

Who we work with

Over 250 EPDs have already been published, and many more are currently undergoing development and verification. Our EPD scheme has:

- Trade association members members such as Brick Development Association, Wood for Good and UK Cares.

- Large national and global manufacturers such as Hanson and Hempel.

- Small and start up manufacturers such as Kenoteq, Addagrip and Ecotherm.

Route 1: BRE Consultancy

One option for getting an EPD works like this:

- Client completes data collection form

- BRE completes the modelling and produces draft EPD

- Client reviews

- Draft sent for verification

- Verified and published

Route 2: BRE LINA tool subscription

The second option for getting an EPD involves the LINA tool:

- Client subscribes to LINA tool

- Client uploads required data into LINA

- Client produces draft EPD

- Draft sent for verification

- Verified and published

How to get an EPD for a product

Step 2: Engage with an LCA consultant

Your consultant may be internal to your organisation, from BRE or an independently qualified third-party. They will help you decide which type of EPD is right for you.

Step 3: Verification

Your EPD, with the product data you have provided, will then be submitted to BRE as the independent verifier.

Step 4: Issue and publication

BRE is a EPD programme operator and provides a publication service. This will include loading your verified EPD on to GreenBook Live and also on to the Eco Platform.

EPD operators can have mutual recognition with other EPD programmes around the world. Eco Platform is aimed at further harmonisation of EPD in Europe and responding to new initiatives and demands such as product environmental footprinting. BRE is founding member and sits on the board of Ecoplatform.

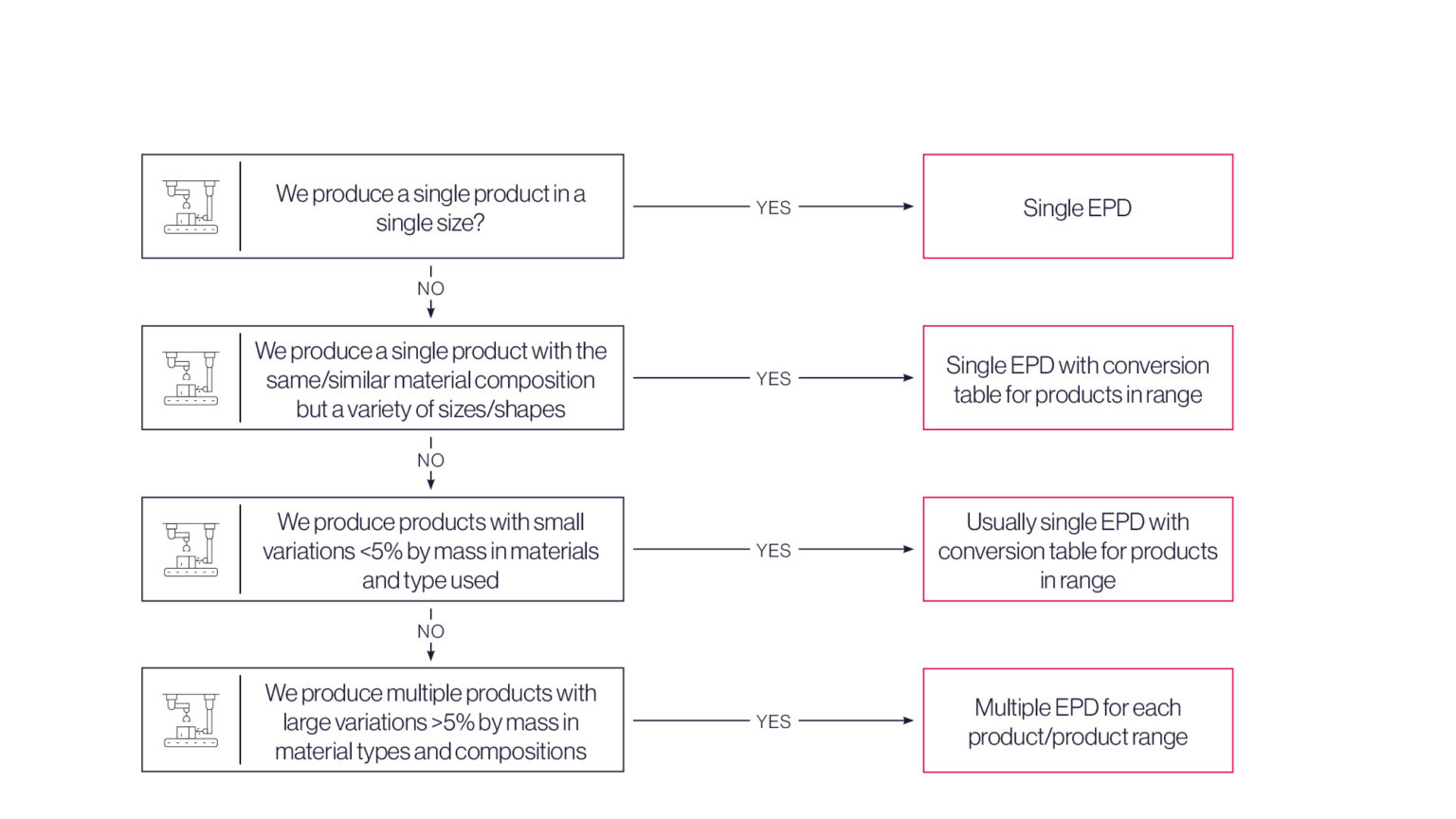

Can I group products in a single EPD?

While it is generally good practise to produce a single EPD; providing verified transparency of each products environmental impacts, there are many cases where multiple products are combined in a single EPD. For example:

Product range EPD. Small changes to EPD such as colour variation or other differences in the make-up of the product that are unlikely to affect the results significantly can be grouped. The representativeness of averages must be documented in the EPD and will typically declare an average or worst case. Products may be doing themselves a disservice in terms of performance if they are grouped into an average with higher impacts and designers may avoid specifying the product. Sensitivities should be run during the LCA to understand how significant the differences in products within a range are.

Scale factor EPD. Where scaling of impacts per declared unit is not linear, scaling factors can be applied. A range of scaling factors may be documented in the EPD for different products in the range such as differing sizes or compositions. This approach is reliant on the EPD user to understand what the scaling factor is and adjust the results appropriately, something that can be challenging when they are machine-read within LCA tools.

If the variance within the product range is high, separate EPDs are recommended. The data within EPD is increasingly being used to inform design decision making and good performing products will be more likely to be specified if they have an individual EPD rather than being grouped into a poorer performing averages.

Where individual EPD are required, generator tools can be a very cost effective method to generate a large volume. They can automate the process based on a small number of material inputs. If you would like to know more please contact us .

How many EPDs do I need?